/FBT-3%20Images%20and%20Videos/FBT-3%20full%20image.png?width=1920&height=1080&name=FBT-3%20full%20image.png)

REQUEST A QUOTE

touchscreen interface and data acquisition

The FBT-3 comes with an inbuilt touch screen interface with an IP65 rating to handle the demanding laboratory environment. Coupled with state-of-the-art data acquisition hardware and electronics, the FBT-3 can handle the most demanding testing applications in its small and compact form factor.

/FBT-3%20Images%20and%20Videos/FBT3_Touch%20screen.gif)

INDUSTRY LEADING FEATURES AND TECHNOLOGIES

/Website%20-%20Four%20Ball%20Tester%20(FBT-3)/Four-Ball-Tester-FBT-3-Screen-On.png)

FOUR BALL TESTER BECOMES SMART AND COMPACT

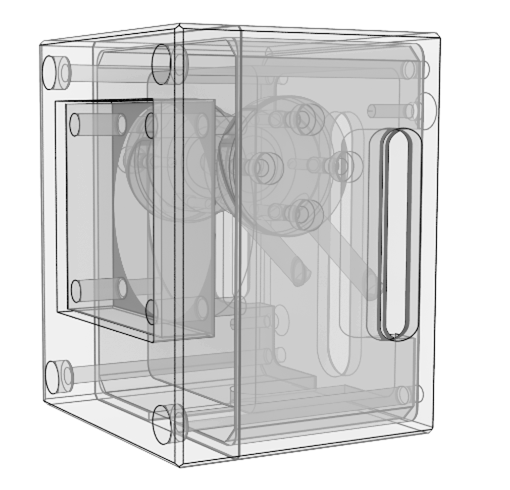

Robust tabletop instrument designed to be the workhorse of lubricant labs. The new FBT-3 occupies a small space (40 x 60 x 85 cm). It is designed to characterize the wear preventive (WP) and extreme pressure (EP) properties of lubricants. It is comprised of pneumatic chambers, piston, and normal load sensor, they work in tandem to achieve the user defined load controls. Automated loading is much appreciated in determining load wear index and incipient seizure load. As it carries a simplified test setup and intuitive software interface, you can run up to 15 EP tests per hour. The control and data acquisition system are designed for full touch compatibility.

ASTM, DIN, IP COMPLIANT

Ducom FBT-3 is compatible to achieve a maximum load of 12000 N, maximum speed of 3000 rpm and maximum temperature of 200 °C. It can comply with ASTM, DIN and IP test standards for WP and EP behavior of any lubricants. Check out the FBT-3 performance (ASTM on Tribology Lab Performance).

state of the art patented technology

Patented friction force measurement technology for unparalleled measurement accuracy. Rapidly increasing lubricant quality standards demand the use of more sensitive measurement techniques to evaluate lubricants, and FBT-3 delivers on this.

Thermal Management Unit

Oils and greases in critical machine elements operates at temperatures above 200 °C. An optional advanced thermal management system in the FBT-3 allows tests on lubricant up to 200 °C.

Read more about the novel thermal management unit in four ball tester.

/FBT-3%20Images%20and%20Videos/FBT%20UI.gif)

intuitive user interface (UI)

The control and data acquisition system are designed for full touch compatibility. The pre-configured test protocols allow users with minimal training to still set up tests that follow the desired standards. The software also allows easy customization of test protocols when your needs exceed the scope of standard test procedures.

unique image acquisition sysytem (ias)

The inconvenience of removing each ball from the ball pot, followed by trial - error method to focus and measure the ball wear scar is made obsolete. The Image Acquisition System can house the entire ball pot after EP and WP tests. It comes complete with integrated camera, optics, lighting, and software. The integrated smart scar measurement technology (available on select systems) can assist users in wear scar area calculation, greatly improving quality of measurements.

/Website%20-%20Four%20Ball%20Tester%20(FBT-3)/Image-Acquisition-System-FBT-3-Standalone.png)

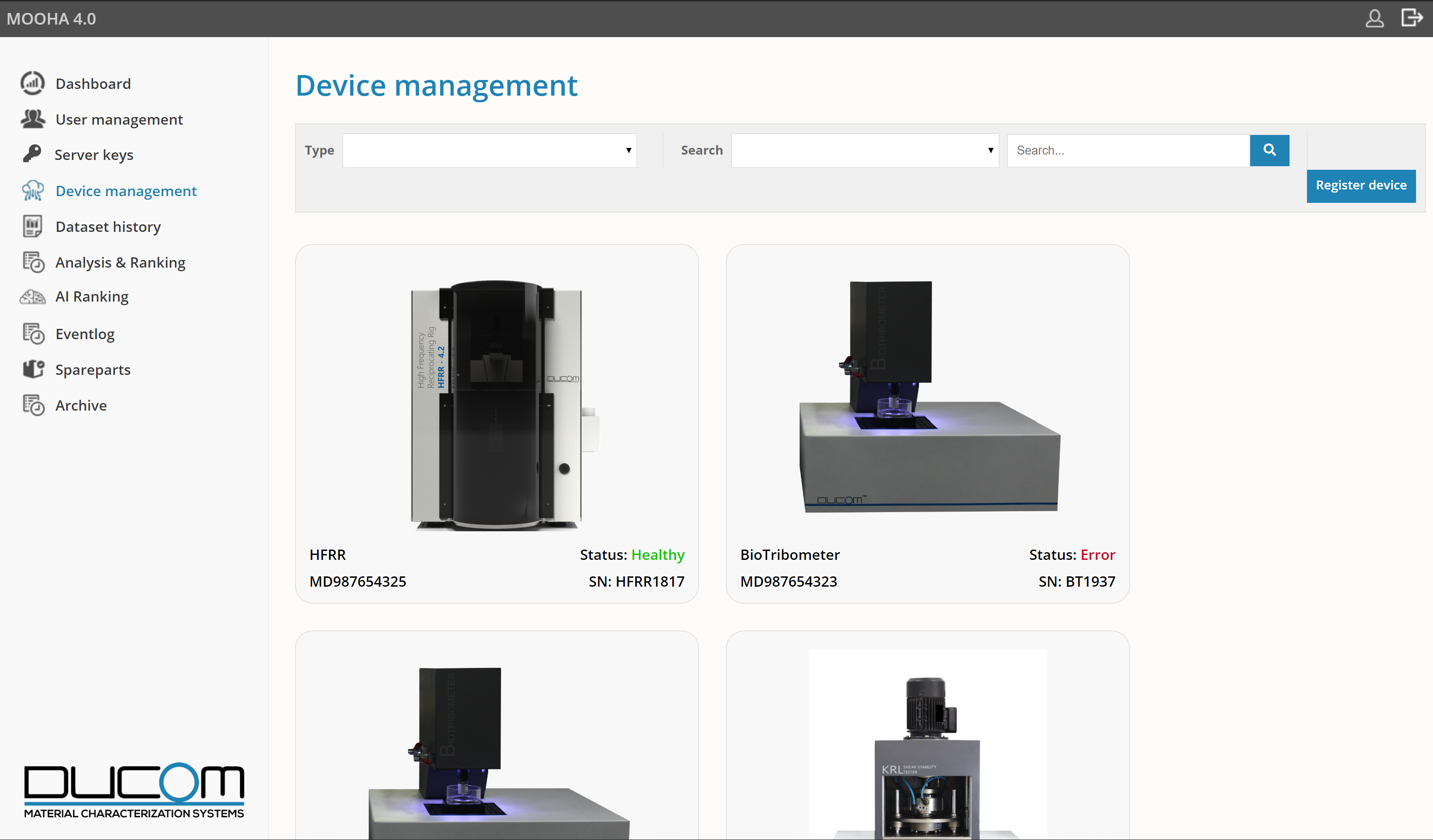

MOOHA - THE DIGITAL ASSISTANT FOR YOUR LAB

MOOHA is an A.I. enabled digital assistant that can be used together with, or in place of your Laboratory Information Management System (LIMS). It has powerful device management, reporting, statistics and support functionalities.

MOOHA is a digital assistant that can help with keeping your lab instruments in excellent health, and your test data secure and easily accessible. Its built-in automatic logging and reporting functions keep data tamper proof and reliable and complete logbook of your instrument is automatically generated while maintaining secure and automated audit trails.

MOOHA is available on desktop and mobile platforms.

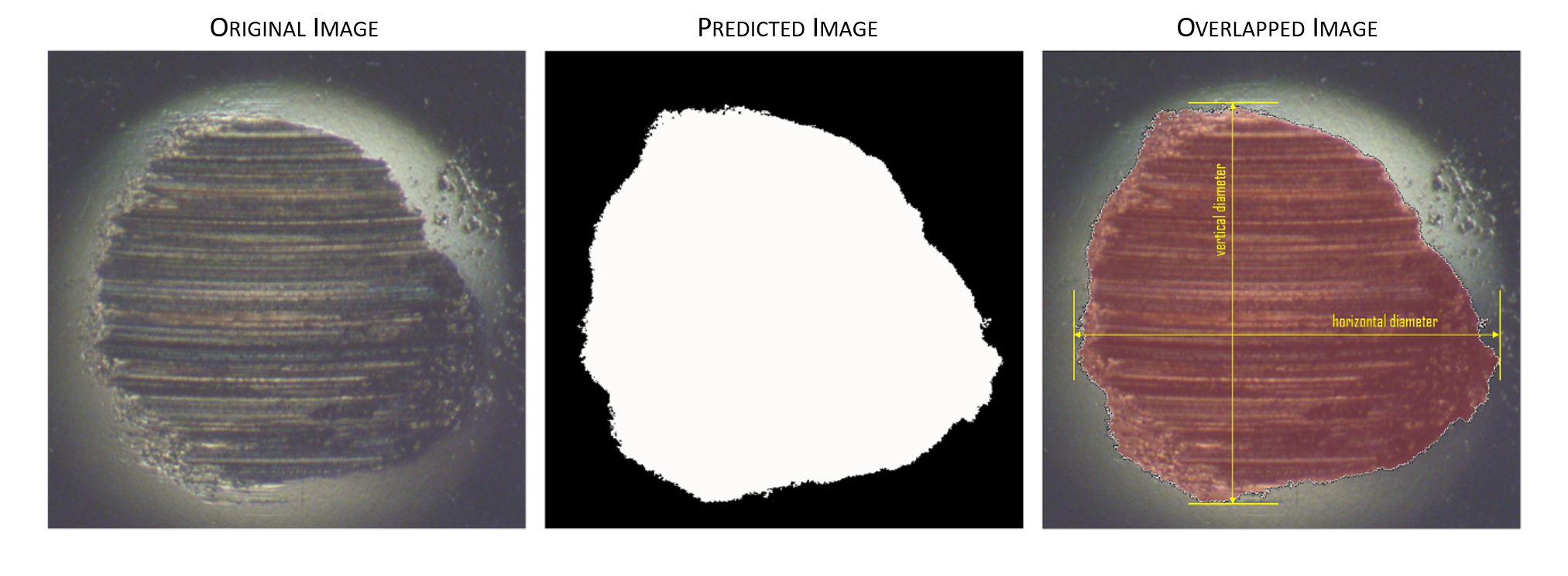

Automatic Scar Prediction

THE POWER OF ARTIFICIAL INTELLIGENCE (A.I.)

Every FBT-3 test is concluded by measuring the wear scar on the test specimens. This has so far been the most manual aspect of the FBT-3 testing and prone to user errors and interpretation. The difficulty in visual observation of scars further increases the test variability. With our proprietary automatic scar prediction software, you can now harness the power of Artificial Intelligence (A.I.) to automatically make consistent and precise wear scar measurements, overcoming the human error and greatly reducing the test variability.

Full compliance with global test standards

![]()

The FBT-3 is fully compliant with global standards for extreme pressure and wear preventive properties of lubricants. With test protocols embedded in the software, you can run tests in accordance with ASTM, DIN, ISO and IP at the click of a button. This means less user training requirements, fewer errors, and lower costs of operations.

- EXTREME PRESSURE PROPERTIES

ASTM D2783: Standard Test Method for Measurement of Extreme-Pressure Properties of Lubricating Fluids (Four-Ball Method)

ASTM D2596: Standard Test Method for Measurement of Extreme-Pressure Properties of Lubricating Grease (Four-Ball Method)

IP 239: Determination of extreme pressure and anti-wear properties of lubricating fluids and greases - Four ball method (European conditions)

DIN 51350-2: Testing of lubricants - Testing in the four-ball tester - Part 2: Determination of welding load of liquid lubricants

DIN 51350-4: Testing of lubricants - Testing in the four-ball tester - Part 4: Determination of welding load of consistent lubricants

ISO 20623:2017: Petroleum and related products — Determination of the extreme-pressure and anti-wear properties of lubricants — Four-ball method (European conditions) - WEAR PREVENTIVE PROPERTIES

ASTM D4172: Standard Test Method for Wear Preventive Characteristics of Lubricating Fluid (Four-Ball Method)

ASTM D2266: Standard Test Method for Wear Preventive Characteristics of Lubricating Grease (Four-Ball Method)

ASTM D5183: Standard Test Method for Determination of the Coefficient of Friction of Lubricants Using the Four-Ball Wear Test Machine

DIN 51350-3: Testing of lubricants - Testing in the four-ball tester - Part 3: Determination of wearing characteristics of liquid lubricants

DIN 51350-5: Testing of lubricants - Testing in the four-ball tester - Part 5: Determination of wearing characteristics for consistent lubricants

Technical Specifications

Load: 100 to 10,000 N

Friction Force: 0 to 200 N

Need to discuss this with your team? Download this data sheet.

Technical DatasheetOPTIONS

MOOHA - Digital Lab Assistant

Consumables

APPLICATIONS INCLUDE

- Determine extreme pressure (EP), wear preventive (WP), frictional and fatigue behavior of lubricants.

- Determine the incipient seizure and load wear index of lubricants. Check out our article on On the mechanism of lubricant additives using four ball tester

- Bench mark the lubricants against the competitors in the market.

- Measure and compare the WP / EP of nanoparticles derived from carbon, metal oxide, sulphides, and nanocomposites. Check out our article on How to investigate nanoadditives by NIS USA?

- Compare the performance of lubricants at different loads, temperatures, base oils, additives, suppliers, etc.

• Compare and estimate the deterioration of lubricant quality by comparing fresh and used oil. Check out our article on Oil Aging: How to investigate the inevitable in the lab? - Investigate the performance of polymeric materials in lubricants used to achieve better shear stability and minimize viscosity loss.

- Lubrication efficacy of biodegradable/vegetable oils compared to mineral/synthetic base oils.

TESTIMONIALS

"The WP and EP test data from Ducom FBT-3 were within the acceptable precision limits when compared to test data from other four ball manufacturers"

Anonymous, UK

"Ducom has developed a superior four ball tester that complies with safety and productivity standards in Repsol."

Carlos Fernandes Sanchez, Repsol S.A., Spain

"Few components in FBT-3 had to be replaced and then calibrated, it would take weeks due to Covid, Ducom sent us a calibrated four ball tester to continue the tests during the part replacement. It was much appreciated gesture"

Anonymous - Netherlands

%20-%20PNG.png?width=925&height=246&name=Ducom%20-%20Logo%20-%20Full%20-%20Vector%20(90%20Gray%20and%20Light%20Blue-Inverted)%20-%20PNG.png)